We are committed to developing and supplying enduring, environmentally and socially responsible cladding systems.

Endlessly recyclable material

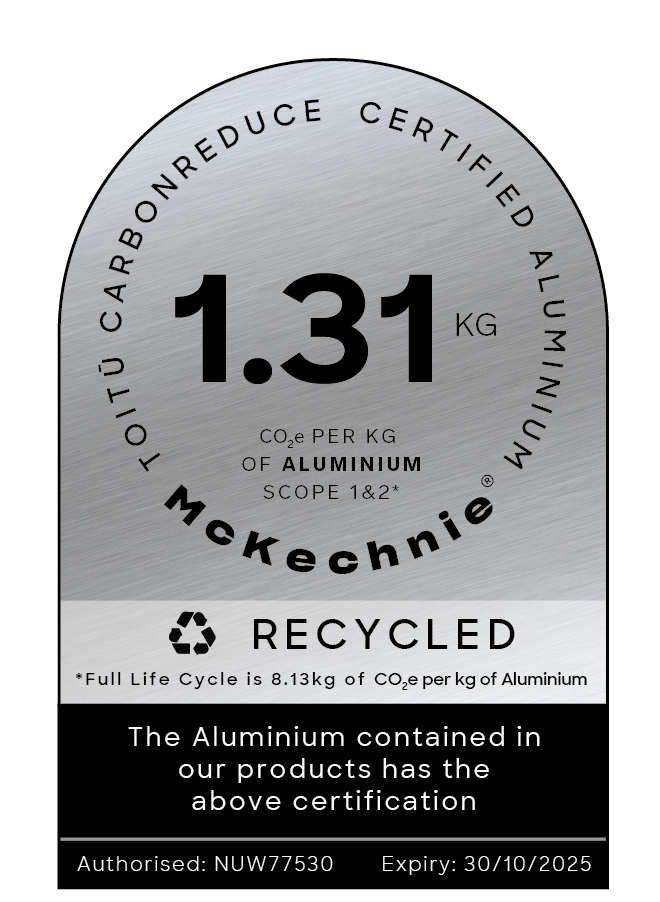

The great attraction of aluminium is that it is an incredibly durable and endlessly recyclable material, with the remelting process never degrading structural integrity or durability. Our New Plymouth-based manufacturing partner, McKechnie® Aluminium, is a leader in sustainable processes and are currently the only manufacturer in New Zealand with its own aluminium recycling remelt facility.

All Nu-Wall Cladding products are high in recycled material content which results in a lower carbon footprint. Products contain a high percentage of recycled aluminium, with the remelting process requiring only 5% of the energy needed to create virgin aluminium. The remaining virgin content is sourced from various suppliers, including Tiwai Point smelter in the South Island. The result is that NuWall boards have a carbon footprint that is significantly lower than the global average of virgin aluminium.

Minimal lifecycle costs and resources

A low-maintenance product, Nu-Wall cladding effectively extends the overall lifespan of structures by eliminating the need for resourceintensive re-oiling or repainting required for various cladding alternatives. Nu-Wall cladding remains in ‘as new’ condition for many years, providing an attractive return on investment and peace of mind for asset owners.

What is the Toitū Certification?

Established in 2001 as a government-owned Crown Research Institute, Toitū provides independent advice to help businesses measure, manage and reduce their carbon footprint and operate more sustainably. With certifications grounded in science and aligned with international standards like ISO14067:2018, giving you the confidence that these certifications are recognised locally and in most international markets.

Nu-Wall EPD

An Environmental Product Declaration (EPD) tells the environmental story of a product over its life cycle in a format that is clear and transparent. It is science-based, independently verified and publicly available. EPDs are often compared to the nutrition labels on food products.

EPDs help manufacturers translate complex sustainability information about their product’s environmental footprint into simpler information that governments, companies, industry associations and end consumers can trust to make decisions.

An EPD communicates the environmental impacts at different stages in a product’s life cycle. This may include the carbon emitted when it’s made, and any emissions that pollute the air, land or waterways during its use.

Download Nu-Wall's EPD Document's belowThis EPD covers the environmental impacts of Nu-Wall Boards - Powder Coated when used both inside and outside a building envelope subject to treatment level.

This EPD is based on a ‘cradle-to-gate’ Life Cycle Assessment (LCA), with end-of-life options included. ‘cradle’ refers to the raw material extraction and ‘gate’ is the gate of the Nu-Wall manufacturing facilities as the product is ready to be dispatched to customers